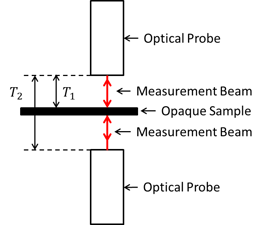

Abstract— Lumetrics has developed a fixture that expands precision measurement capabilities of the commercialized low-coherence interferometer, OptiGauge II, to materials that are not translucent to its measurement beam light of 1310nm. The fixture contains two probes oriented towards each other and an optical reference surface. The effects of the temperature on the measurement accuracy are eliminated via a calibration procedure conducted before the measurement.

Abstract— Lumetrics has developed a fixture that expands precision measurement capabilities of the commercialized low-coherence interferometer, OptiGauge II, to materials that are not translucent to its measurement beam light of 1310nm. The fixture contains two probes oriented towards each other and an optical reference surface. The effects of the temperature on the measurement accuracy are eliminated via a calibration procedure conducted before the measurement.

Lumetrics is the market leader in providing highprecision, non-contact optical thickness measurement solutions to medical, scientific, and ophthalmic industries.

The process of manufacturing, forming, and converting metal is a tightly-controlled process. Required tolerances may exceed the practical capabilities of contact mechanical micrometers and gauges. Companies often rely on x-ray and other hazardous radiation-based instruments for online measurement.

Lumetrics markets a low-coherence interferometer which uses safe levels of the infrared (1310nm) light to measure a large variety of translucent materials in a non-contact manner. In the case of opaque materials, such as metal, Lumetrics offers a special fixture and software bundle that allows for obtaining highly accurate (reaching 100 nm accuracy in laboratory environment) thickness measurements of such materials.

COMMENTS