1) Absorbable Stents - Read a great article on how a New Standard Focuses on Testing of Absorbable Stents

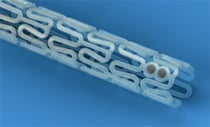

We can measure absorbable stents. Picture credit: Abbott Vascular's polymer-based Absorb bioresorbable stent.

We can measure absorbable stents. Picture credit: Abbott Vascular's polymer-based Absorb bioresorbable stent.

2. Food Packaging- We can make sure your food packaging is of the highest quality, meets all safety standards, and prevents waste during manufacturing. It's also very crucial to make sure you don't have to issue a recall due to safety issues. Here's an example of why food packaging is so important. Read more here on how Lumetrics' can solve your food packaging safety challenges

3) Medical Balloons- When it comes to medical balloon measurement, Lumetrics® has the capabilities to replace archaic methods of inspection like the micrometer and razor blade. Our measurement systems are a seamless replacement to provide highly accurate, consistent, non-contact, and non-destructive measurements for a variety of medical device products. Read More

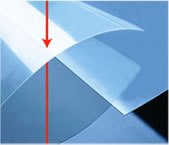

4) Cell Phone Glass- From our file of “Thickness Measurement” challenges comes Cell phone glass and its structure. It’s very easy for the OptiGauge to measure multiple layers of a product, but how does an engineer know what is good or bad? Protective film, adhesive, outer glass- no problem. We’re often asked to measure the structure, especially the inner layers, which is one of our many areas of expertise. We provide the gold standard of thickness measurement- generating results with an accuracy of .000004". Read our white paper on cell phone glass measurement!

5) Multilayer Film Thickness Measurement- Multilayer film thickness measurement provides a challenge to the manufacturers who produce complex films or other light-permeable materials, and the quality personnel who need to inspect them. Antiquated measurement methods are time consuming and often inaccurate. The results may depend more on the accuracy of a weight scale or the sharpness of a razor blade than a true measurement of the product. New, stricter FDA regulations require many products/materials to have NIST traceable inspection history, as well as information that cannot be obtained using obsolete inspection methods. Lumetrics® is the film thickness measurement authority. The OptiGauge™ uses innovative light technology to provide non-destructive, accurate, real-time, film thickness measurement for all types of multilayer films and thin film coatings whether co-extruded, coated, or laminated. Read More

6) Tubing Thickness Measurement- In order to meet stringent manufacturing requirements, medical tubing manufacturers strive to maintain consistent and precise wall thickness, inside diameter (ID), outside diameter (OD), concentricity, and the reduction of ovality. Accurate thickness measurement of these components is critical to product quality and the safe practice of patient care.

Utilizing innovative optical measurement technology, Lumetrics’ OptiGauge™ is a non-contact medical tubing and catheter thickness measurement system in use throughout the medical industry for dimensional testing of all types of extruded tubing products. Lumetrics has also developed another new measurement fixture- the LumetriScan™ 360. The LumetriScan™ 360 provides a system for advanced catheter measurement that provides consistent, NIST traceable, and real-time measurement in the production process. More Information

7) Opthalmic Product Thickness Measurement- Today's ophthalmic products require precise dimensional control to provide the fit and comfort that doctors require and customers demand. Lumetrics' OptiGauge™ can be integrated into the production line or the quality assessment process, providing real-time measurement of ophthalmic products. The OptiGauge™ provides peace of mind to production and QA by providing inspection on up to 100 percent of all products. Read More about Lumetrics' ophthalmic metrology solutions

COMMENTS