Optical Thickness Gauge Applications

Meet Quality and Compliance Standards, Increase Yield

Your company’s integrity is tied to the quality of your products. That’s why top-tier manufacturing companies and OEMs turn to Lumetrics to achieve submicron-level accuracy to guarantee the highest level of quality in their advanced products. Our non-contact thickness measurement and optical inspection systems deliver real-time measurements in a non-destructive way, making our systems ideal for the metrology of medical devices, multilayer films, silicon wafers, automotive windshields, float glass, contact lenses, and intraocular lenses.

Increase yields without sacrificing quality using non-destructive testing to measure barrier films, coatings, and more.

Learn More

Highly accurate measurements of catheters, balloons, IV bags, and medical device components.

Learn More

Reduce risk and save time in automotive wedge angle measurement, float glass measurement, and other advanced applications.

Learn More

Measure parameters including diameter, CT, SAG, and label power of contact lenses and intraocular lenses.

Learn More

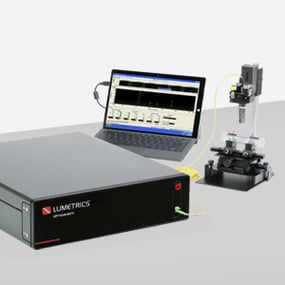

Fast, Accurate, Non-Destructive Optical Metrology for Precision Manufacturing

Lumetrics’ breakthrough precision thickness measurement technology is fast, accurate, flexible, and scalable to most QA laboratories, R&D centers, or production lines. Choose one of our off-the-shelf products or explore custom metrology solutions and discovery services to meet your application’s requirements.

Our systems use low-coherence interferometry, wavefront sensors, and other optical methods so you can meet compliance.